Rig Mounted Brush Mower GC600 Maruzenkogyo

商品番号:MAR-016E

Most powerful in this class!

・Most powerful in this class!

Max allowable intake pressure:27.5MPa

B.P.M.:500~950

・Suitable for a variety of work.

1.For breaking concrete and rock

2.For driving in anchor and pile

3.For digging out hard ground

4.For tamping soil and sand

5.For cutting and breaking asphalt

・Easy to attach with various excavator.

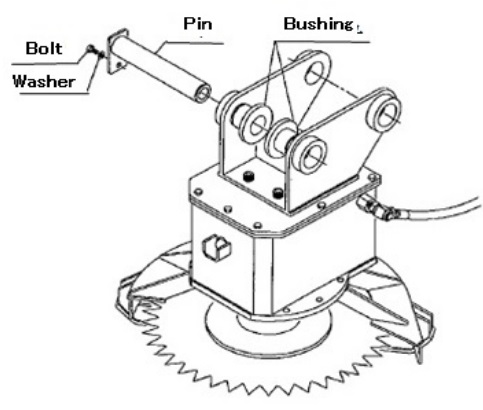

2 pcs of PIN, 4 pcs of BUSH,

and hoses are required to attach with an excavator.

Please let us know if you want to ask more...

・your information(name, address, telephone number)

・quantity

・delivery address

| 販売単位: | |

|---|---|

| 価格: | お問合せください |

| MODEL | GC600 |

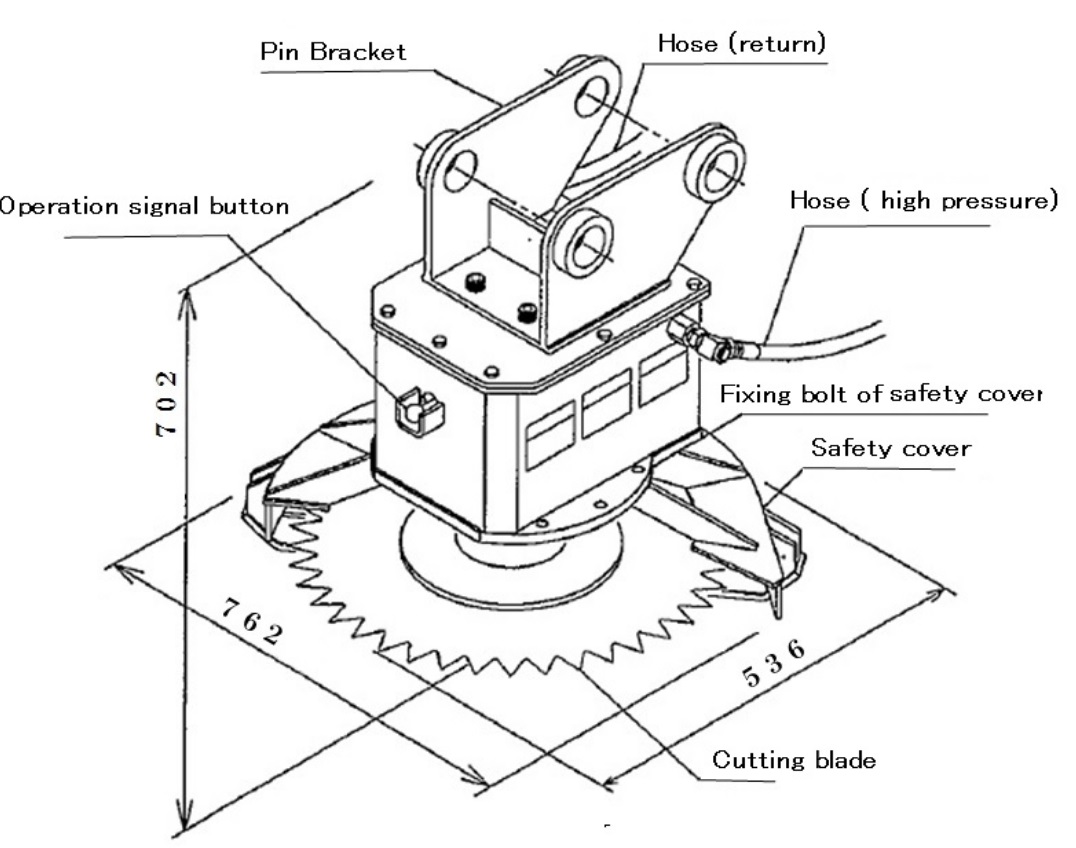

| dimensions(mm) | 762×536×702 |

| weight(kg) | 97 (hose bracket included) |

| hydraulic moter | gear motor |

| flow range(ℓ/min) | 25~60 |

| relief set pressure(MPa) | 17.2 |

| allowable back pressure(ℓ/min) | Max 2.0 |

| standard blade size(mm) | OD 610*thickness 2.3*teeth 40 |

| blade R.P.M. | 3,600 |

| torque(N・m) | max 12.7 |

| blade speed(m/S) | 120 |

| connection | G12 |

| safety cover rotation angle | ±45° |

| hydraulic piping | without PTO circuit |

| suitable machine (weight) (t) | 0.07~0.25 |

| suitable machine (weight) (t) | 2~5.5 |

| capacity(m2/h) | 500~600 |

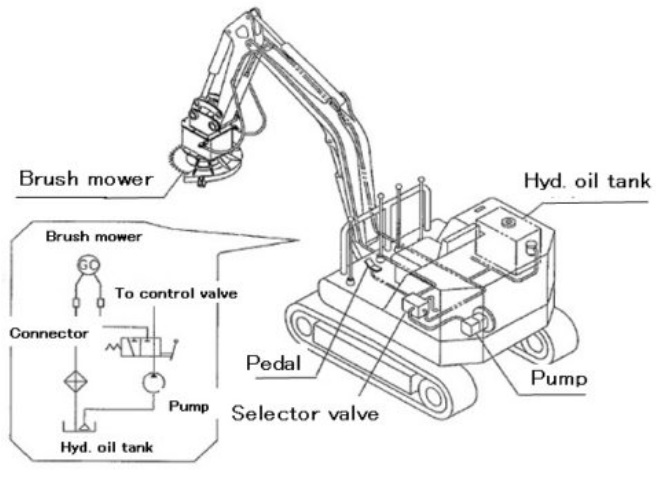

[Hydraulic Piping]

Piping is different according to the models and types of excavator.

Refer the following basic piping for your attachment of machine and piping.

HOW TO USE

(1) Attaching Grass Mower to Excavator

1. Detach the bucket of excavator and set the arm ends inside of bracket of grass mower.

2. Attach the grass mower to the bucket links of arm with 2 pins.

3. Connect hoses of grass mower to the pipes of bucket circuit or PTO circuit if equipped.

* Connect the hoses of mower to be in position of upper hose to high pressure hose and lower hose to return hose.

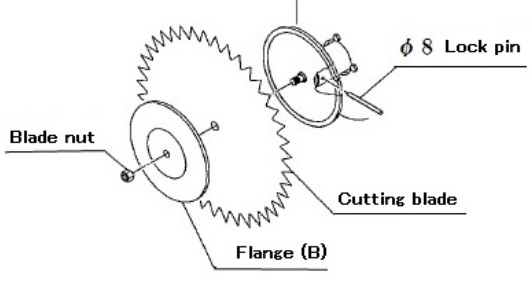

(2) Attachment of Blade

1. Insert φ8mm bar or plus driver into the hole of bearing to stop the rotation of saw shaft.

2. Set saw blade between flange (A) and flange (B) and fix it with nut.

* Tightening torque: 150-180N/m

3. Take out φ8mm bar.

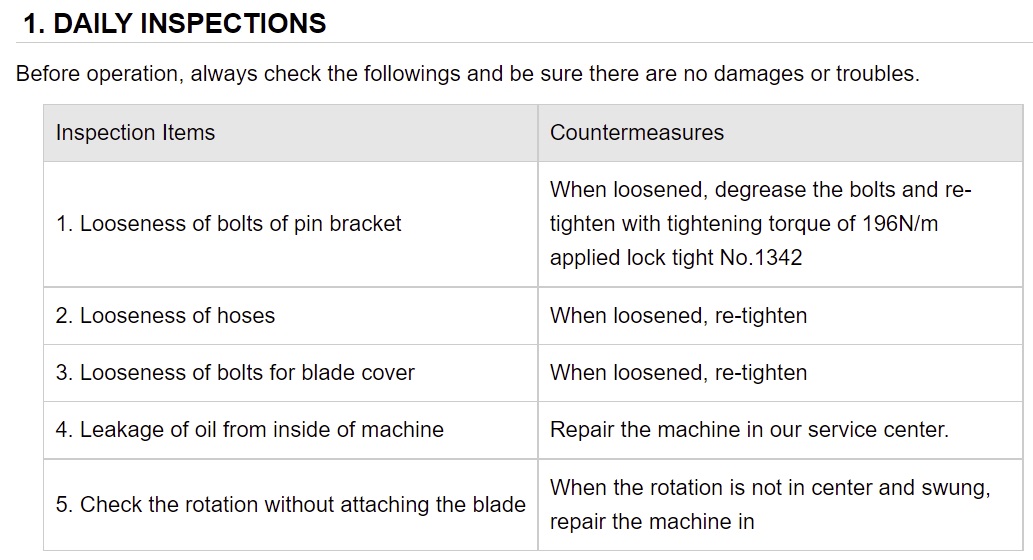

MAINTENANCE

(1) Check the volume and dirt of hydraulic oil in the tank.

The dirt of hydraulic oil may cause the damage of motor and flow divider of GC600.

Replace the oil when it is dirty.

(2) When stored GC600, dismount it from excavator and apply anti-corrosive oil.

Hoses should be stored connected the couplers.

(3) The nut (counter clockwise) for setting the blade should be replaced max after 5 times use.

Don’t use the nut over 5 times. Also, don’t use the nut except genuine one.

Failure to observe this can result the serious personal injuries.

(4) Be sure the tightening torque of the nut of blade.

Tightening torque: 150-180N/m.