Rig Mounted Breaker BH501 Maruzenkogyo

商品番号:MAR-018E

Simple structure with excellent durability

・Only 47 kg, but extremely powerful.

Max allowable intake pressure:20.6MPa

B.P.M.:700~1,000bpm

・Easy to attach with various excavators.

2 pcs of PIN, 4 pcs of BUSH,

and hoses are required to attach with an excavator.

Please let us know if you want to ask more...

・your information(name, address, telephone number)

・quantity

・delivery address

| 販売単位: | |

|---|---|

| 価格: | お問合せください |

| MODEL | BH501 |

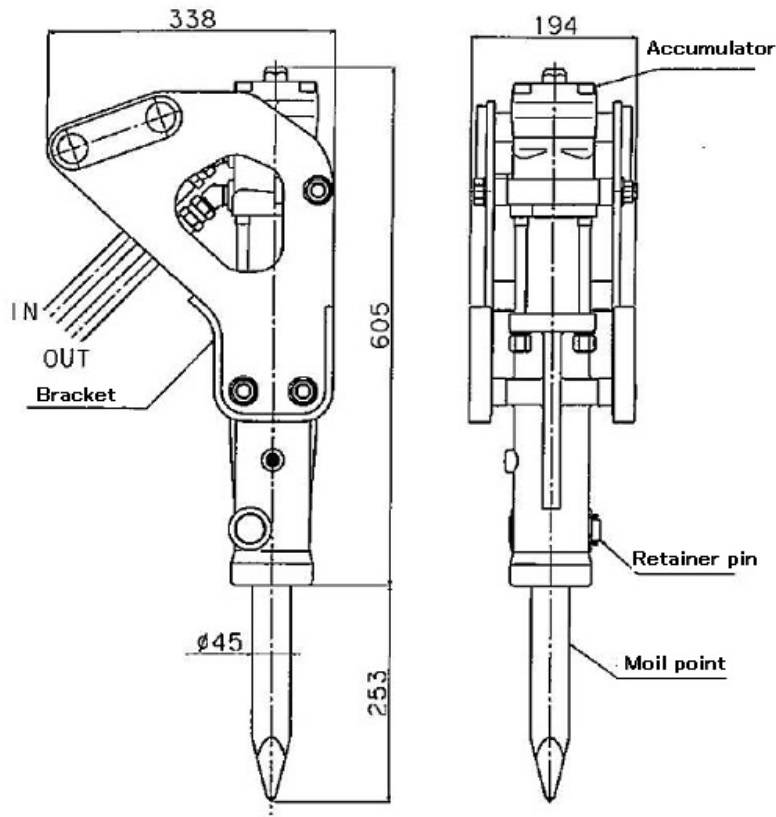

| dimensions(mm) | 605×338×194 |

| weight(kg) | 47 |

| working pressure(MPa) | 8.8~13.7 |

| allowable pressure(ℓ/min) | 20.5 |

| required oil flow / b.p.m | 12~16ℓ/min → 600~800bpm 16~20ℓ/min → 800~1050bpm 20~25ℓ/min → 1050~1200bpm |

| moil point | length 450mm, dia 45mm, weight 4.5kg |

| connection | 3/8inch couplers (hose : 1/2") |

| suitable machine (bucket capacity) (m3) | 0.02 |

| suitable machine (weight) (t) | 0.8~1.0 |

[STRUCTURE]

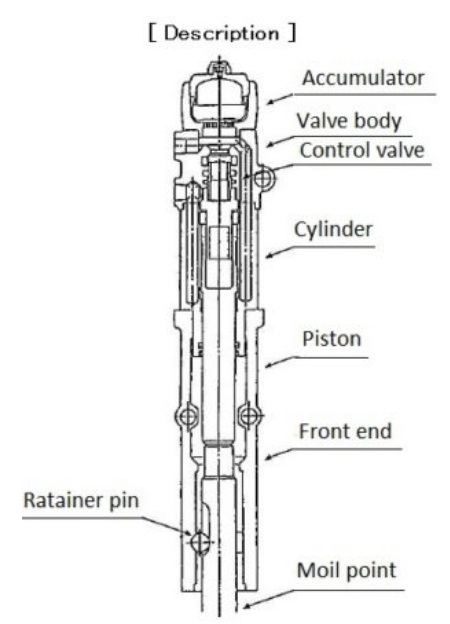

1. An accumulator is equipped on the top to get breaker hit stable.

2. Control Valve inside Valve Body switches flow of oil according to the movement position of piston and controls striking part.

3. Piston goes up and down in cylinder and strikes a moil point.

4. Valve Body trough Front End are tighten by 4 pcs of bolts.

5. Oil flow in from upper high pressure side, and come out from lower low pressure side.

6. Moil point can be attached on and off easily by only one retainer pin.

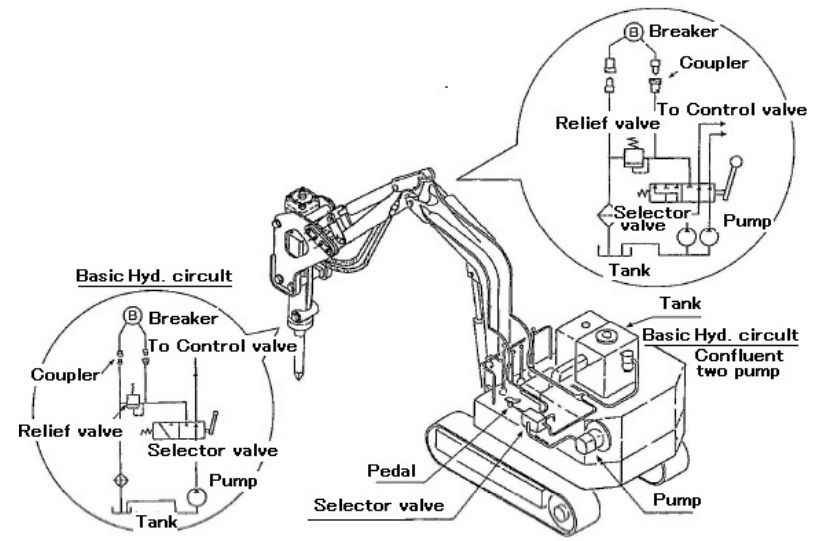

[HYDRAULIC PIPING]

1. Piping is different according to the models and types of excavator.

Refer to the below circuit as a base.

2. Keep the relief-set pressure in the range of 13.7~20.6MPa.

HOW TO USE

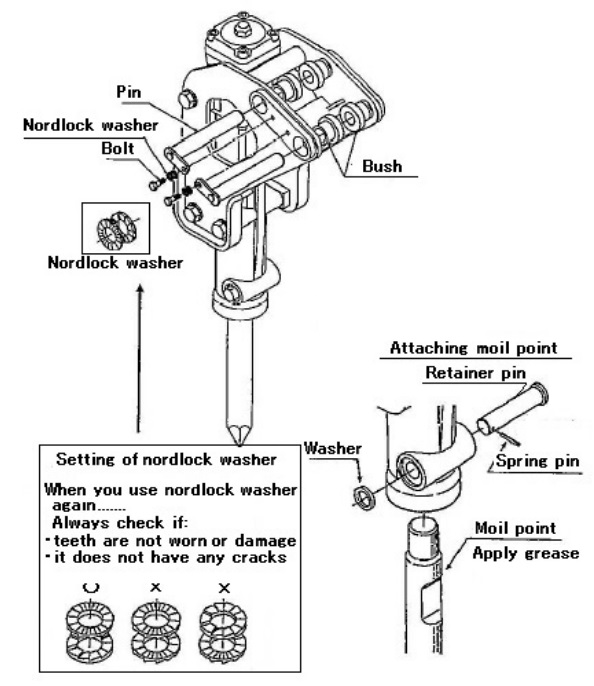

1. Use 4 pcs of bush and 2 pcs of pin to mount the breaker on excavator.

2. Grease in and outside of bush when attaching it to the bracket.

3. Keep the breaker horizontal and attach arm of excavator and bucket link together with 2 pcs of pin.

4. Insert pin and stop it with hex bolt and spring washer.

Tighten Torque 8N・m

5. Connect hydraulic hoses to the PTO port on excavator.

Be sure to turn off engine this time.

Connect the hoses correctly. Upper side hose of the breaker is IN, and lower side hose is OUT.

6. Grease moil point and insert to the breaker.

Insert retainer pin and fix it with washer and spring pin.

7. After operation, turn off the engine when you take out moil point.

Be sure to wear glove since moil point would get very hot after operation.

8. To remove the breaker, place the breaker horizontally on the ground, depressurize the breaker circuit, and then stop the engine.

While the breaker is being used, temperature of each section rises as oil temperature rises.

Use gloves to avoid unnecessary damage due to high temperature.

MAINTENANCE

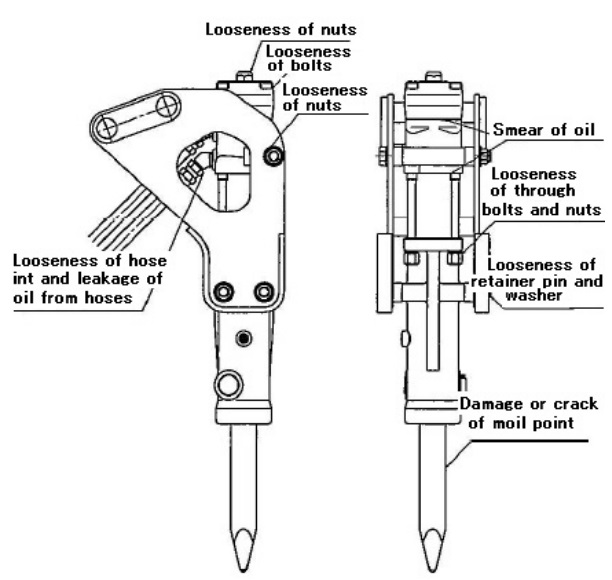

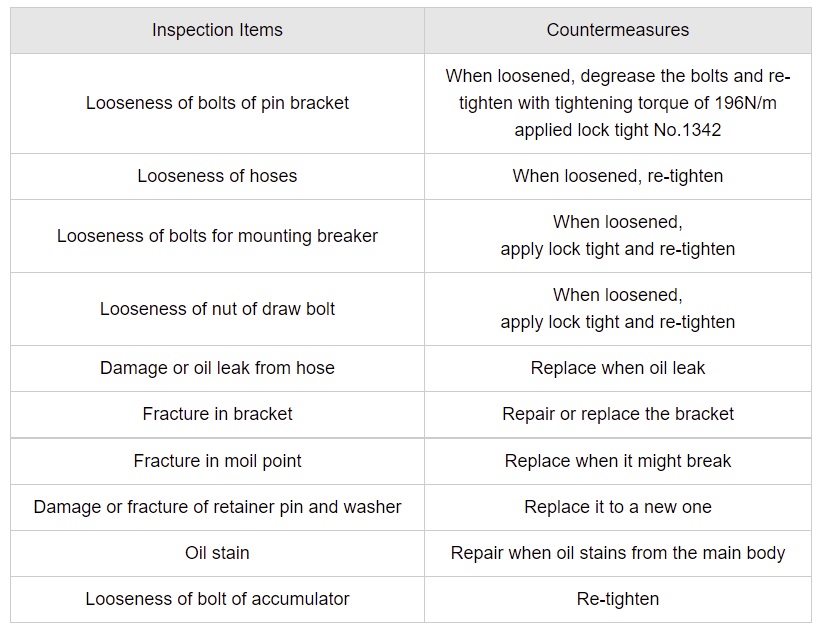

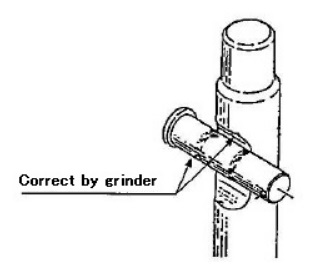

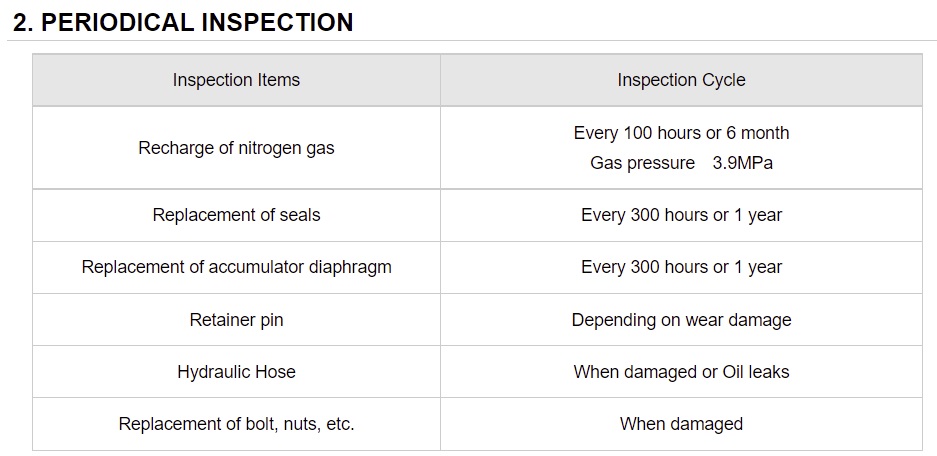

1. DAILY INSPECTIONS

Before operation, always check the followings and be sure there are no damages or troubles.

Please make sure to stop the engine before checking.

(1) Check the volume and dirt of hydraulic oil in the tank.

The dirt of hydraulic oil may cause the damage to the breaker.

Replace the oil when it is dirty.

(2) Grease the chisel

Grease the chisel enough, or the chisel burns stuck or wears earlier.

Grease to the nipple on the front end id the chisel grease is dry during operation.

(Grease with a gun with chisel inserted.)

Grease 4-5 times with a grease gun at the beginning of daily operation.

(3) Check if the contacting parts of the retainer pin and the chisel is swollen.

If so, plane it with a grinder.