|

|

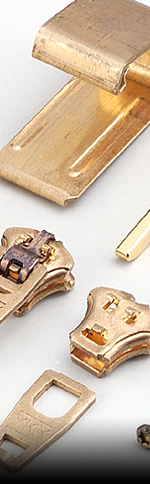

Description of Material |

|

|

|

HD-12S and HD-12H are copper alloys with iron and

nickel added to a titanium alloy.

Iron age-hardens as iron-titanium and nickel age hardens

as nickel-titanium, producing a heat resistant special

copper alloy for electric conductivity and a high-tensile

special copper alloy for electric conductivity. |

|

| HD-12S : |

This alloy excels in heat resistance, thermal conductivity

and is the material

of the high electric conductivity (IACS 60% or more). |

|

| HD-12H : |

This alloy is high strength, wear resistance and

high electric conductivity

(IACS 40 to 60%) material for high-tensile and high

electric conductivity. |

|

-What is age hardening ?

|

Age hardening refers to stabilizing changes

in characteristic of steel products; in

this case, certain heat treatments are

applied to facilitate these changes and

then the material is artificially aged

so that it hardens. |

|

|

|

|

|

Processing Properties (Applicable to HD-12S and HD-12H) |

|

|

|

| Item |

Details |

| Forging |

Extremely good forgeability in hot, warm and

cold etc. Paticularly excels in cold pressure

molding, which requires working under high speed

and high pressure. |

| Bending / Drawing / Spinning

/ Machining |

Good workability in bending, drawing, spinning

and machining processing.

Particularly, it has good bending performance,

allows for easy deep drawing. |

| Plating / Soldering / Etching

/ Welding |

Plating, soldering, etching and weldability

are all good. |

|

|

|

|